Camera imaging sensors placed adjacent to a surface diffusing the collimated light of a laser can sense the resulting surface-dependent speckle pattern. The pattern oscillates if the surface oscillates, leading to the possibility of remote vibrometry.

This project was completed as part of a semester project at ETH Zürich's Sensing, Interaction & Perception Lab under the supervision of Prof. Dr. Christian Holz and Paul Streli.

Problem

Vibration sensing enables condition monitoring and predictive maintenance of industrial equipment by detecting mechanical faults before catastrophic failure occurs. While cameras are low cost, easy to use and highly sensitive, they have relatively low frame-rate and are a poor choice for high rate oscillations.

Traditional vibration sensors require physical coupling to the measured surface using adhesive or glue, bringing the burden of cable management. Wireless sensors need battery replacement and receiving stations.

Remote vibration sensing would offer:

- No physical contact with monitored equipment

- No cable management or battery replacement

- Ability to monitor many objects simultaneously

- Faster installation and maintenance

- Higher bandwidth than camera-based approaches

Approach

Developed a discrete photodetector array to increase measurement bandwidth while maintaining the sensitivity an off-the-shelf imaging sensor provides. The system essentially creates a discrete image sensor - a 3x3 grid of high-speed photodetectors that can capture speckle patterns at much higher rates than conventional cameras.

Detection Principle

When laser light hits an optically rough surface (surface height variations on the order of laser wavelength), it produces a locally unique and stationary interference pattern called a speckle pattern. This pattern results from the superposition of coherent light waves with different path lengths due to the surface's microscopic imperfections.

When the surface is mechanically deformed, the pattern changes. If the surface is translated under the laser light, the pattern appears to shift.

System Design

The backscattered light intensity $I_b$ at distance $d$ is proportional to the laser power and decays quadratically with distance:

$$I_b = \frac{P \cdot \rho}{2\pi d^2}$$

where $P$ is the laser power (W), $\rho$ is surface reflectivity, and $d$ is distance (m).

A photodiode converts this light intensity into current:

$$I_{\text{photo}} = I_b \cdot A_{\text{PD}} \cdot R$$

where $A_{\text{PD}}$ is the photodiode area (mm²) and $R$ is photodiode responsivity (A/W).

Using typical values ($R = 0.5$ A/W, $A_{\text{PD}} = 2$ mm², $P = 1$ mW, $d = 0.3$ m), we're left with tiny photocurrents in the 500 pA range.

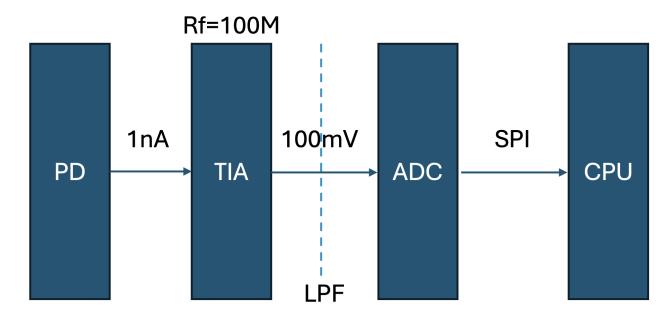

Hardware Implementation

Amplification:

A transimpedance amplifier (TIA) converts photodiode current to voltage:

$$V_{\text{out}} = R_f \cdot I_{\text{in}}$$

where $R_f$ is the feedback resistance. The bandwidth is defined by:

$$f_{-3\text{dB}} = \frac{1}{2\pi R_f C_f}$$

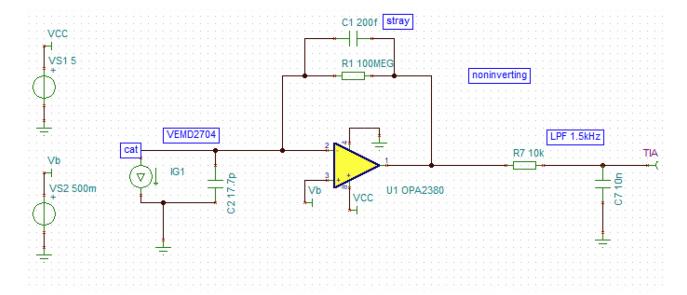

We use a 100 MΩ feedback resistor to achieve 100 mV AC output from 1 nA peak-to-peak photocurrent. With minimal feedback capacitance (0.2 pF stray capacitance), the amplifier bandwidth reaches 7.9 kHz.

Components:

- 3x3 photodiode grid (VEMD2704 by Vishay, 1.5 mm² each)

- OPA2380 JFET input op-amps (low noise, single supply)

- 850 nm IR bandpass filter

- MCC128 ADC (16-bit, 100 kSPS total, 4 kHz per channel)

- RC low pass filter (1.5 kHz cutoff for anti-aliasing)

Signal Processing

To convert the 9-channel photodiode readings into a single vibrometry signal, we compute inter-channel variance. First, we remove common-mode fluctuations:

$$s_i(t) = r_i(t) - \frac{1}{n}\sum_{k=1}^{n} r_k(t)$$

where $r_i(t)$ is the raw intensity reading from channel $i$ and $n=9$. Then we compute inter-channel variance:

$$V(t) = \frac{2}{n(n-1)} \sum_{i=1}^{n-1} \sum_{j=i+1}^{n} |s_i(t) - s_j(t)|$$

This metric quantifies the average magnitude of pairwise intensity differences between spatial channels. Changes in $V(t)$ over time indicate surface motion and vibration while being robust to common-mode noise.

Results

The discrete sensor achieves a bandwidth of 1 kHz, exceeding conventional cameras by an order of magnitude while maintaining comparable sensitivity to a Raspberry Pi HQ camera (12.3 MP).

Tests conducted with 850 nm IR lasers:

- Evaluated discrete IR lasers with different beam patterns

- Tested IR dot projectors (Intel RealSense D415)

- Defined detection limits based on surface reflectivity

- Found that using multiple aligned laser sources simultaneously improves SNR without degrading signal quality

The system successfully detected vibrations on test equipment, validating the concept for industrial condition monitoring applications. This demonstrates that high-frequency vibration monitoring can transition from contact-based sensors to distributed remote sensing using discrete photodetector arrays.

Implementation

Hardware design files and software available on GitHub: github.com/bitmorse/specklesensor

Full technical paper from ETH Zürich semester project (January 2024) available in the repository.